14 Results

-

04 Sep

04 SepDaVinci 112 Test Socket: A Game-Changer in High-Speed Chip Testing

The DaVinci 112 is specifically engineered to handle the advanced requirements of today's most dynamic markets, including Cloud Computing, Data Centers, Artificial Intelligence, and Connected Automotive.

-

27 Nov

27 NovFAQs at Smiths Interconnect: test sockets, capabilities, and support

After over 40 years of industry experience, Plastronics was acquired by Smiths Interconnect as the company’s one-stop shop for burn-in and reliability testing. As the complementary in-house burn-in division, we have also brought a wealth of knowledge and expertise in socket design and manufacturing.

-

01 Nov

01 NovWhat is thermal simulation and why is it important to reliability burn-in testing?

Not every semiconductor manufacturer utilizes thermal simulation in their reliability testing setup. Lower power burn-in allows for an acceptable temperature rise within the package/die in a traditional burn-in chamber running at 125°C. As packages in burn-in are moving to higher power output, socket and burn-in systems may need to have enhanced features to manage the desired target die temps.

-

01 Sep

01 SepOptimizing Production Test of QFN-packaged IC’s for Consumer, Automotive, Industrial and Power Applications.

Where best-in-class electrical requirements intersect with a need for a small outline, low-profile footprint, IC designers are increasingly migrating to QFN packages. Meeting these testing challenges requires a test socket solution that is robust, reliable, and electrically “clean.”

-

07 Aug

07 AugImproving time- and cost- efficiency in reliability burn-in testing

When companies develop new devices, they must ensure there are no failures in the field. This means that thorough reliability burn-in testing must take place from the start to avoid malfunctions down the road.

-

21 Jun

21 JunHigh-Power Burn-In Testing in 2023: How to Overcome the Extreme

The tech zeitgeist is all about the extreme. The more advanced our devices become by the day, the more they evolve – and consumers’ expectations with them.

-

?ext=.jpg&width=480&resizemode=force) 01 May

01 MayRaising the Bar of Burn-In Testing Sockets

Burn-in testing is widely used as an aid in producing failure-free electronic components. When scientifically planned and conducted, burn-in-testing sockets offer one of the most effective methods of reliability screening at the component level. Testing during production plays a vital role in ensuring reliability and repeatability. Semiconductor manufacturing plants perform tests at each stage of production to eliminate defective parts as early as possible while precisely controlling each process parameter of the chip.

-

05 Apr

05 AprRethinking Blind Mate Connectors to Increase Reliability in Miniaturized Electronics Assembly

Creating more compact electronic components with higher functionality is a challenge for all electronics manufacturers. Whatever industry you're in, creating consumer, business, or military-grade electronics, the challenge presents itself, and the stakes are high. As electronics are expected to continue shrinking while increasing capabilities, blind mating connectors are required to meet those same size and functionality requirements.

-

13 Mar

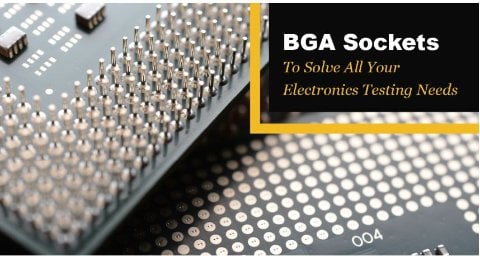

13 MarBGA Sockets To Solve All Your Electronics Testing Needs

Plastronics, a Smiths Interconnect technology brand, is a global provider of innovation for semiconductor reliability testing, meeting the industry’s burn-in socket needs for more than 40 years. It all started when our company invented the first open-top, application-specific socket for production burn-in of LCC packages. This innovation helped semiconductor manufacturers significantly increase their throughput and decrease costs.

-

14 Feb

14 FebChallenges Semiconductor Package Size and Pitch Face in Shrinking Consumer Electronics

Tiny computers, smartphones, and small electronic devices that industry leaders and other companies have popularized are forcing the hand of semiconductor package designers to shrink the package to fit within these little hand-held gadgets. The demand for technology applications, such as smart homes, smart manufacturing, smart medical care, and automotive electronics, continues to increase. At the same time, the requirements of continuous miniaturization and functional diversification of electronic product demands also increase.

-

01 Nov

01 NovEnsure Reliability in Edge Computing with Burn-In Testing

Retail. Manufacturing. Government. Healthcare. Distribution. Choose an industry, and edge computing is there helping organizations thrive. Every industry has more data to generate, control, share, and save, which means that through 2022 and beyond, more enterprises will use the edge to benefit their business.

-

05 Sep

05 SepCustom Connectors VS Catalog Connectors: Benefit Breakdown and Challenges

There's no escaping the expectations to create more compact electronic components with higher functionality. Designing shrinking electronics is a challenge for all electronics manufacturers. Whatever industry you're in and no matter if you’re creating consumer, business, or military-grade electronics, there is a demand for building smaller, smarter, and sturdier electronics.

-

08 Aug

08 AugIs it really that hard to improve chip test performance?

In the digital era, semiconductor chips are present in almost every aspect of our lives. Whether it is from microwave ovens to computers, cell phones, computer central processing units, and other electronic devices there are a variety of chips installed.

-

14 Dec

14 DecAccelerating Device Bring-Up and Production Ramp for WLCSP 5G Mobile IC’s

As mobile phone electronics continue to shrink, WLCSP has become the de-facto packaging solution for IC’s going into today’s flagship handsets. Manufacturers need solutions to rapidly debug their new silicon, and quickly ramp it to HVM while achieving aggressive DPPB quality levels.