Tag Results

5 Results

-

07 Aug

07 AugImproving time- and cost- efficiency in reliability burn-in testing

When companies develop new devices, they must ensure there are no failures in the field. This means that thorough reliability burn-in testing must take place from the start to avoid malfunctions down the road.

-

21 Jun

21 JunHigh-Power Burn-In Testing in 2023: How to Overcome the Extreme

The tech zeitgeist is all about the extreme. The more advanced our devices become by the day, the more they evolve – and consumers’ expectations with them.

-

?ext=.jpg&width=480&resizemode=force) 01 May

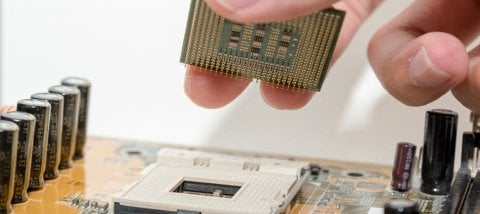

01 MayRaising the Bar of Burn-In Testing Sockets

Burn-in testing is widely used as an aid in producing failure-free electronic components. When scientifically planned and conducted, burn-in-testing sockets offer one of the most effective methods of reliability screening at the component level. Testing during production plays a vital role in ensuring reliability and repeatability. Semiconductor manufacturing plants perform tests at each stage of production to eliminate defective parts as early as possible while precisely controlling each process parameter of the chip.

-

13 Mar

13 MarBGA Sockets To Solve All Your Electronics Testing Needs

Plastronics, a Smiths Interconnect technology brand, is a global provider of innovation for semiconductor reliability testing, meeting the industry’s burn-in socket needs for more than 40 years. It all started when our company invented the first open-top, application-specific socket for production burn-in of LCC packages. This innovation helped semiconductor manufacturers significantly increase their throughput and decrease costs.

-

14 Feb

14 FebChallenges Semiconductor Package Size and Pitch Face in Shrinking Consumer Electronics

Tiny computers, smartphones, and small electronic devices that industry leaders and other companies have popularized are forcing the hand of semiconductor package designers to shrink the package to fit within these little hand-held gadgets. The demand for technology applications, such as smart homes, smart manufacturing, smart medical care, and automotive electronics, continues to increase. At the same time, the requirements of continuous miniaturization and functional diversification of electronic product demands also increase.