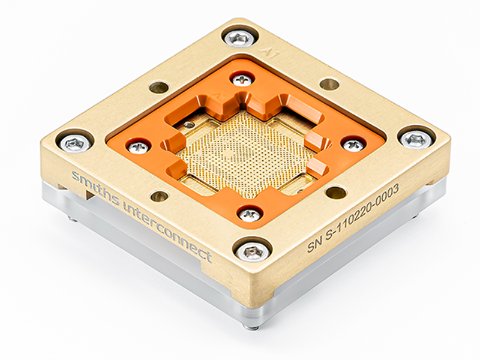

DaVinci sockets for high speed test offer a revolutionary solution for production ruggedness and signal integrity. The unique IM material used in DaVinci's construction permits a truly coaxial structure from tip to tip, yielding the industry-leading bandwidths available from a highly compliant contactor. An internally developed product, IM is a conductive socket material which is selectively insulated with an exceptionally tough coating. This allows signal probes to be retained in the contactor in a coaxial structure without the use of sleeves or plates, producing matched impedance from one end of the probe to the other. This permits single ended bandwidths as high as 67 GHz and digital data rates of as much as 56 Gbps. DaVinci products offer exceptional rigidity and dimensional accuracy, and are impervious to hygroscopic growth. They are thermally conductive, permitting control of device temperature from the lead side.

- Matched coaxial impedance accuracy due to the patented, unique signal probe design and the IM material socket housing.

- IM-coated socket body has long lasting insulation which enables the use of Smiths Interconnect’s renowned single-ended spring probes for lower power inductance, higher current carrying capacity, and lower contact resistance.

- Spring probe technology ensures reliable performance, simple in-house maintenance and replacement

Smiths Interconnect’s design team utilizes extensive system simulation models throughout product development to ensure an optimal solution for each test environment. We also perform design validation and RF measurements which exceed the industry’s stringent test requirements ensuring excellent out of the box performance and quick test system bring up.

{^youtubevideo|(width)480|(height)295|(rel)True|(autoplay)False|(fs)True|(url)https://www.youtube.com/watch?v=7Zu_wKzbUJQ^}