The most cost-effective, high-performance contact

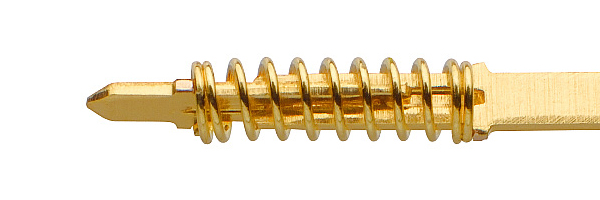

The H-Pin® provides the mechanical and electrical benefits of a spring probe pin with the cost savings and manufacturing process control of a fully automated stamping and assembly manufacturing process.

The H-Pin is a stamped spring probe pin made from the assembly of three components: two beryllium copper stampings and one stainless steel would spring.

Each of these components comes from a fully automated, high -volume manufacturing process.

The H-Pin unique design and its equally special assembly process result in an electrical contact with superior performance, at the same time allowing for an affordable solution for new connector designs.

- The beryllium copper stampings provide reliable and stable conductivity for flat resistance curves, -great current per pin capacity and fast signal speed.

- The stainless steel spring provides mechanical cycle life, shock and vibration endurance and operating temperature well above 220°C.

The H-Pin manufacturing process allows to reduce costs without compromising design. It also provides the peace of mind of quality assurance and reliability that only comes from a fully automated and redundant inspection process.

H-PIN: A STAMPED PIN PROBE THAT WILL FOREVER CHANGE THE WAY YOU DO BUSINESS.

A new approach to pin design, manufacturing, packaging, delivery and price that gives you a high performance contact pin at the lowest cost.

The H-Pin is a stamped spring probe with the mechanical, electrical and thermal performance of a spring probe, and the ease of use and high volume manufacturability of a stamped contact. The H-Pin serves applications without the typical compromises that are generally required when considering cost versus performance.

Excellent mechanical and electrical performance.

Utilizing high volume BeCu stamping technology, combined with a stainless steel spring for mechanical travel, the H-Pin has a working range up to 0.70 mm with a flat spring rate and can be utilized up to 15GHz with -1.0dB loss, carry up to 4 amps of current and withstand temperatures up to 200°C.

High volume stamping and quality control.

From pin one to one million, you’ll get the same pin every time. Because of our automated H-Pin manufacturing process, you’ll be the first person to make contact with your pins.

Stocked inventory and better lead time.

Because of our automated manufacturing process, Plastronics always has the supply you need in inventory.

Limitless Applications.

Historically, options for the burn-in, programming, system-validation and other markets that require 10,000+ insertions and thousands of sockets, have been limited. The H-Pin is the solution.

![]()

Great Price.

Our innovation in pin design, manufacturing, packaging, delivery and price gives you a high-performance contact pin at the lowest cost.

![]()

| FEATURES | BENEFITS |

|---|---|

| 0.40 mm to 0.70 mm Travel | Compliancy for Large Package Warpage |

| Flat Spring Rate | Stable Contact Resistance and Force |

| BeCu H-Pin® | Solid Beam Electrical Performance |

| Stainless Steel Core Spring | Compliancy at High Temperatures (180°C) |

| Bandwidth -1dB @ 15GHz | Correlated BI, System Evaluation and Test |

| Current Carrying Capacity | Reliable Power and Ground Contact |

| High Volume Stamping | Stocked Inventory and Better Lead Time |

| High Volume Stamping | High Volume Capacity and Quality Control |

| Reel-to-Reel Pin Insertion | High Volume Capacity and Ease of Use |