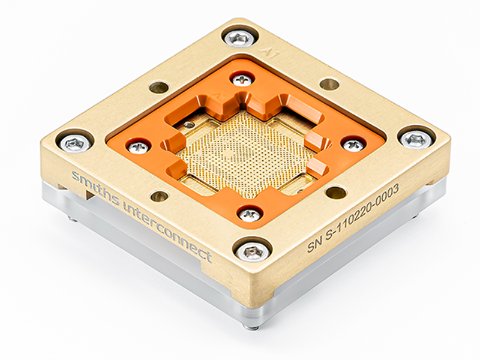

- Configurable design, In-house tooling and molds allow for the lowest cost of test.

- An extensive catalog of standard parts reduces cost and lead time.

- Double-latching clamshell provides ease of use during operation and clearance for lid operation.

- Exceptional electrical performance provides wide RF bandwidth.

Feature Options

- LGA, BGA, and package on package

- Spring loaded plunger

- Heat sink

- HAST venting features

- Integrated thermal control with heater and sensor

- Reverse seating plane

- Max component clearance under the DUT

- High temperature materials for above 200 °C applications