- Guaranteed low and stable insertion loss under maximum power:

- Circulators: 0.11 dB insertion loss with 20 dB minimum Return Loss over -25˚C to +125˚C

- Loads: 20 dB minimum Return Loss over -25˚C to +135˚C

- Multipaction and Corona Test Reports available

- Proven Circulator design tested to 350 Watts CW Power. Unconditionally linear.

- Proven Load design tested to 267 Watts average CW Power

- Tested to meet Electro Magnetic Compatibility (EMC) specification to -80 dBi

- Low Mass – Aluminum Housing with Chromate Finish

- 40 years of Unrivalled Space Heritage

- All testing in compliance with generic space qualification flow, incorporating industry standard power and environmental requirements

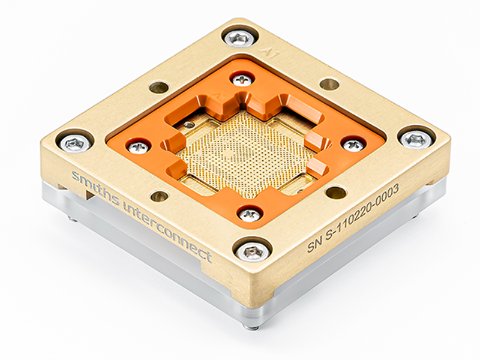

Smiths Interconnect’s SpaceNXT™ product portfolio provides customers with a combination of highly reliable technology and lower cost of ownership that enables operators to overcome potential market entry barriers while enjoying the benefits of an established technology partner.

The SpaceNXT™ Ku-Band High Power family of passive waveguide components are part of Smiths Interconnect’s overarching initiative to create a broad range of readily accessible space qualified waveguide Isolators, Circulators, Terminations, transitions, Hybrids and couplers operating in assigned bands from X to V-Band specifically for space applications.