- Featuring IDI contact technology

- Long cycle life

- Stable contact resistance

- Superior compliance

- Reliable signal integrity

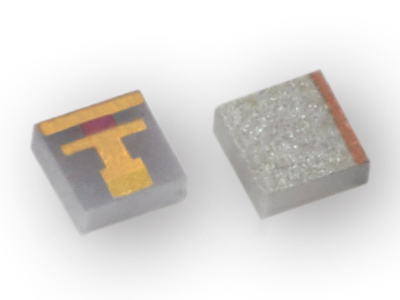

Battery Contacts and Connector Probes are ideal for direct mounting to printed circuit boards The electrical performance is maximized to provide a reliable path for either power supplies or signal paths Typical applications include the connections between a mobile radio's PCB and its battery, a board-to-board interconnect for the docking of a portable device to its programming station, or an interconnect between a camera body and a powered zoom lens.