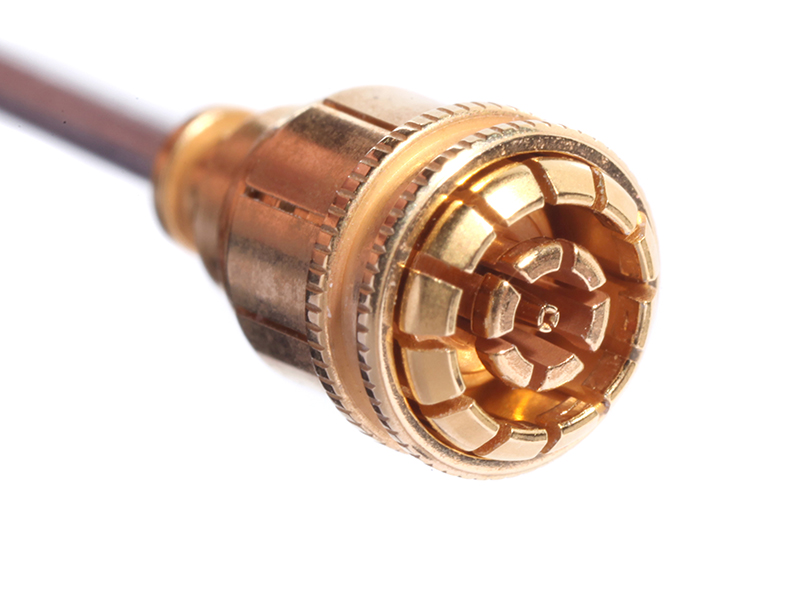

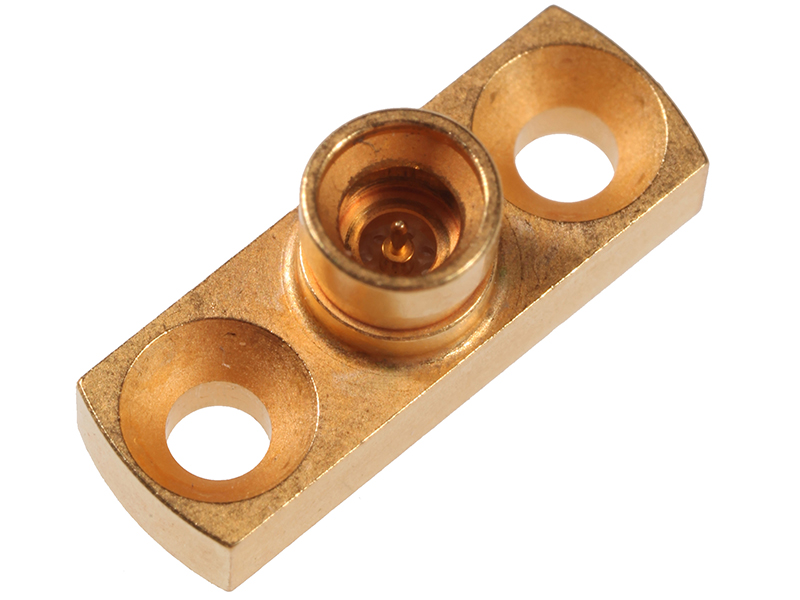

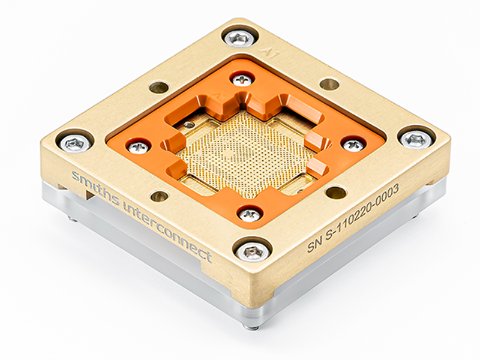

- Small lightweight connector

- High frequency: 110 GHz

- Excellent electrical performance

- Robust locking capability

- Temperature range: -65 °C to 165 °C

- Low insertion force

- Vibration: MIL-STD-202G, Method 204 :

- MIL-STD-202G, Method 213, Condition I

Applications:

- Satellite Communication & Navigation

- Military, Commercial and Scientific Programs

- GEO/MEO/LEO and Small Satellites

- Manned Space Flight

- Electronic warfare

- Unmanned vehicles