- Small: Less than 6 mm high (module and interposer)

- Rugged: MIL-STD 883 shock and vibration qualified

- Sealed: Moisture and thermal shock resistant

- Storage temperature: –57 ºC to100 ºC

- Performance: up to 28 Gbps/channel over a recommended operating temperature range of –40 ºC to 85 ºC

- Sensitivity: –7.5 dBm (typical) for BER 10–12

- Low power consumption: 180 mW/channel

- 4 TRX (4+4)-lane per module (100G, full duplex)

- 12 TX or 12 RX channel per module (300G, half duplex)

- Multimode 850 nm wavelength laser

- Over 60 m reach on OM3 ribbon fiber

- Standard MT parallel fiber connector

- RoHS

- Clock and data recovery, pre-emphasis, and adjustable output

- Monitoring: LOS, RSSI, temperature, etc.

- Integrated microcontroller

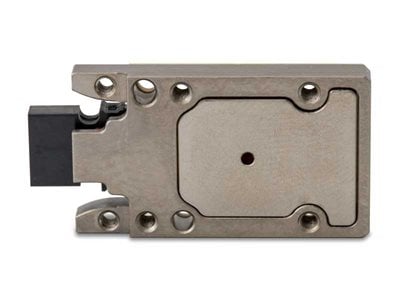

- Attaches to system board with LGA interposer

Applications

- Sensor connectivity including all-digital AESA radars

- High I/O density, high BW communication links

- ISR embedded system

28G Optical Transceivers for Space

Electrical connection with interposers

LightABLE™ and SpaceABLE™ electrical connection with interposers

Optical connection with screw-in connector

Optical connection with MicroClip

Optical Interconnect Design Challenges in Space